Generator Cores for Wind & Hydraulic Power

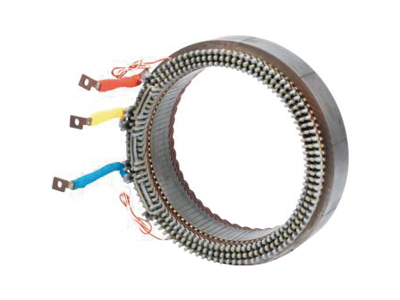

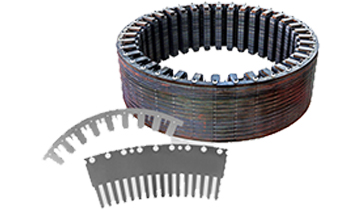

- Our stator and rotor cores support both wind and hydraulic power applications, including plain wind power, high-altitude, low wind speed, offshore wind power, and hydroelectric systems.

- With advanced mold development and manufacturing capabilities, we offer reliable punching sheets and iron cores, customized from samples to mass production.

- Stator Range: 180~8000mm

- Rotor Range: 120~9000mm

- Certification: ISO9001、IATF16949

Generator Cores for Wind and Hydropower Markets

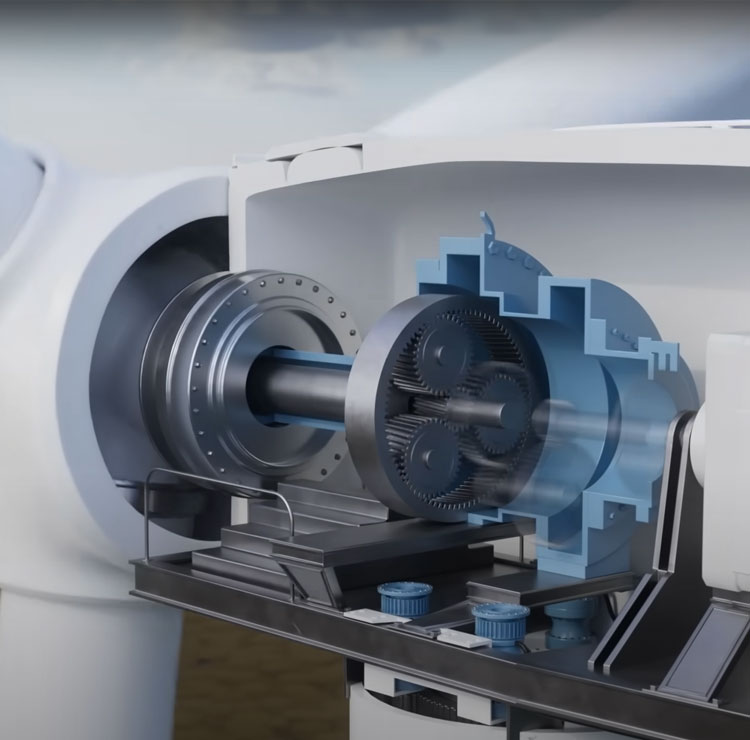

- The market for wind and hydraulic power is growing quickly due to the world's shift to renewable energy sources. Industries are demanding high-efficiency generator cores that enhance energy conversion, reduce losses, and ensure long-term operational stability.

- Innovations in low-loss materials and precision manufacturing are enabling the development of customized cores tailored to various power capacities and environmental conditions.

Wind Power Generation

Used in onshore and offshore turbines, our cores ensure efficient energy conversion, supplying power to residential, commercial, and industrial sectors.

Hydroelectric Power Plants

Found in dams and hydropower stations, our generator cores convert water’s kinetic energy into electricity efficiently.

Microgrid and Off-Grid Systems

Supporting decentralized power solutions, these cores ensure stable electricity supply in remote areas with limited grid access.

Hybrid Renewable Energy Systems

Integrated with solar and battery storage, our generator cores enhance efficiency and reliability in hybrid energy setups.

Marine and Tidal Energy Applications

Utilized in tidal and wave energy systems, these cores convert oceanic movements into sustainable electricity.

Our Sustainable Energy Solutions

Our generator cores enhance energy conversion efficiency in wind and hydro power, ensuring reliable and sustainable electricity generation across multiple applications.