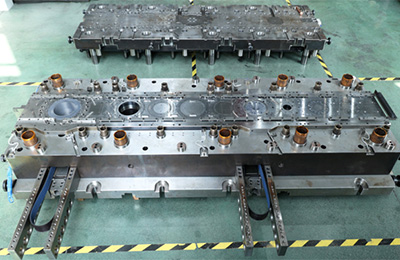

Motor Core Lamination Stamping Dies

- Our in-house die/mold R&D team is responsible for designing, producing, and maintaining stamping dies, ensuring quick resolution of any related issues.

- Our motor lamination stamping dies are made from premium tungsten steel, guaranteeing superior durability and performance.

- 22 Years In Die/ Mold Manufacturing

- Precision and Accuracy: 0.005 mm(0.0002 inches)

- Premium Tungsten Steel Material

- Custom Flexibility

- Quick Resolution of Die-Related Issues

- In-Mold Dispensing Is Mass-Produced

Our Stamping Die Types

Single-Slot Stamping Die

- Designed for single-slot precision punching.

- Ideal for small batch and sample production

- Simple structure, easy to operate.

- High accuracy, minimal material waste.

Compound Stamping Die

- Combines multiple functions in one die.

- Reduces cycle time and increases throughput.

- Perfect for complex, multi-step parts.

- Suitable for medium to high-volume runs.

Progressive Stamping Die

- Optimized for high-speed mass production.

- Increases output and minimizes downtime.

- Durable for high-volume manufacturing.

- Ideal for continuous, automated production processes.

Why We Use Tungsten Steel Material?

High Hardness

Exceptional Wear Resistance

Excellent Heat Resistance

High Strength and Toughness

Precision and Accuracy

Our Stamping Die Design & Manufacturing Capabilities

Design and CAD Modeling

Manufacturing Process

Prototype Testing and Adjustment

Final Inspection and Mass Production

Our Die/Mold Solutions

With extensive mold development experience and a complete process system, we provide customized solutions, ensuring effective support for design, production, and maintenance challenges.

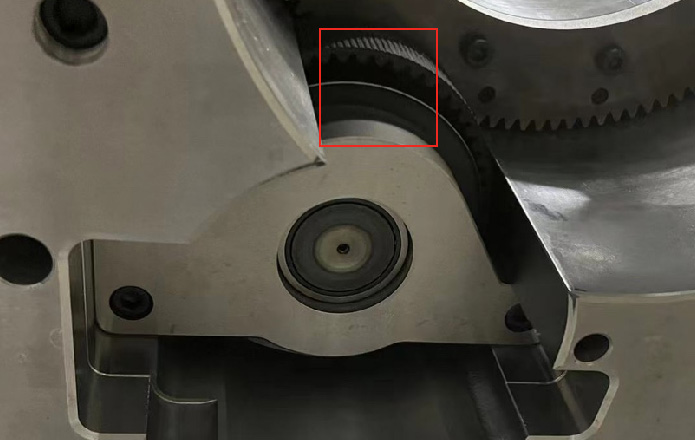

Non-Eccentric Tension Giant Gyro Structure

This solution addresses the issue of high unilateral tension in the synchronous belt of the large rotation structural component of the rotor core within material molds in the industry. Resolving the imbalance in tension, it helps prevent uneven wear and improves product accuracy.

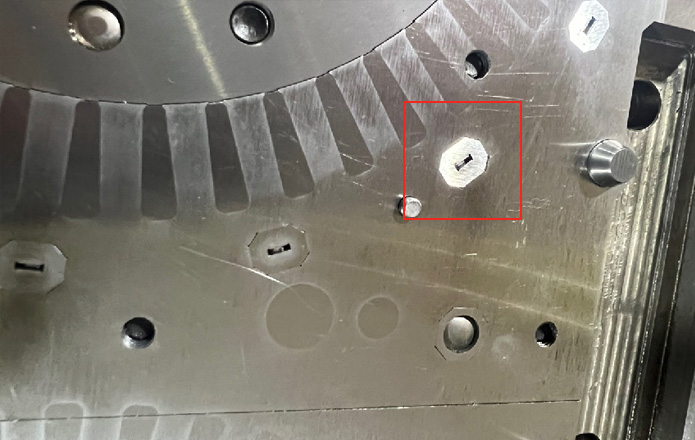

Tungsten Steel Insert Solution for Easy Wear Parts

Stamping Die Manufacturing Videos

General FAQs

What is the lifespan of motor lamination stamping dies?

The lifespan of motor lamination stamping dies depends on usage, material type, and maintenance. Typically, well-made dies can last for millions of cycles before requiring replacement or maintenance.

How do you maintain motor core lamination stamping dies?

Can your motor lamination stamping dies be customized?

In mass production, automated winding machines, quality control processes, and precise material handling ensure consistent winding results across all stators.