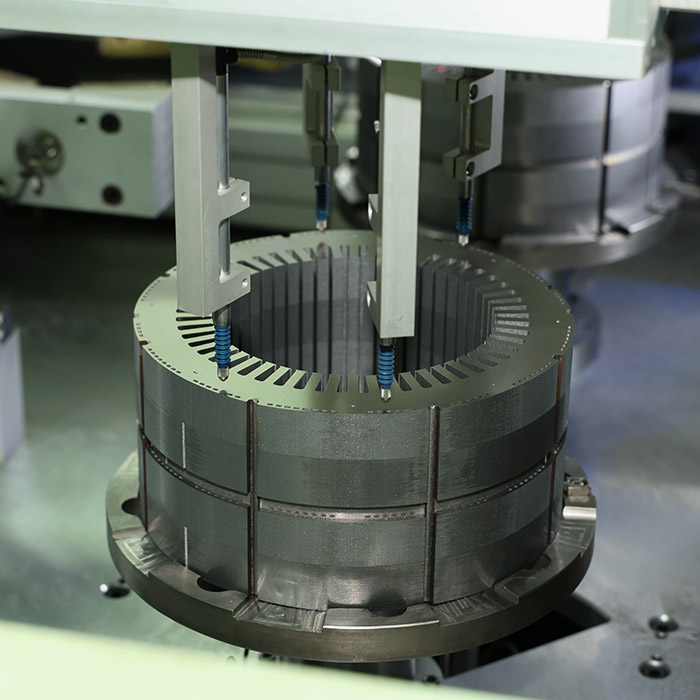

Motor Rotor & Stator Cores for Flywheel Energy Storage

- Our motor rotor and stator cores for flywheel energy storage systems are engineered for maximum energy efficiency and fast response times.

- These high-performance cores play a vital role in storing and releasing energy, supporting the growth of sustainable and reliable energy storage solutions.

Motor Cores for Flywheel Energy Storage Market

- The flywheel energy storage market is rapidly growing, driven by the need for efficient, reliable energy storage solutions. Motor cores play a crucial role in optimizing flywheel systems, providing high-performance, durable components for energy storage and retrieval.

- As industries seek sustainable energy alternatives, the demand for advanced motor cores tailored for flywheel applications continues to rise.

Our motor rotor & stator cores are designed to meet the high-speed requirements of flywheels, offering enhanced efficiency and longevity for energy storage systems.

Flywheel Energy Storage Motor Cores Types We Serve

We provide motor rotor and stator cores, including induction, permanent magnet, and variable reluctance types, ensuring efficient energy conversion and reliable flywheel storage performance.

Induction Motor Cores

Includes Double-fed induction motor cores, providing reliable energy conversion with high efficiency, ideal for flywheel energy storage systems requiring robust performance.

Permanent Magnet Motor Cores

Features Brushless DC Motor (BLDCM) cores and Permanent Magnet Synchronous Motor (PMSM) cores, ensuring low energy losses and high torque in flywheel energy storage applications.

Variable Reluctance Motor Cores

Optimized for flywheel energy storage, these cores offer precise control and efficient energy transfer, with minimal maintenance and high power output.

Key Applications

- Our motor rotor and stator solutions are essential for energy storage systems, offering reliable performance in diverse applications, from power supplies to energy storage.

- Transportation

- Uninterruptible Power Supplies

- Test Laboratories

- Physics Laboratories

- Aircraft Launching Systems

- Spacecraft Energy Storage

- Amusement Rides

- Pulse Power

- Motorsports

- Grid Energy Storage

- Wind Turbines

- Toggle Action Presses

General FAQs

What materials are used in your flywheel energy storage motor cores?

Motor cores are typically made from high-strength alloys, silicon steel, and permanent magnets to optimize energy efficiency, minimize losses, and withstand mechanical stresses during energy storage and retrieval.

What is the lifespan of your flywheel energy storage motor core?

Flywheel motor cores typically last 10-20 years, depending on operating conditions, material quality, and maintenance, as they undergo wear due to continuous energy conversion and mechanical stresses.

What are the economic benefits of using Flywheel Energy Storage motor cores?

They offer fast charging and discharging times, long lifespans, and low operational costs, making them economically attractive for many industrial applications.

Can your flywheel rotors be customized for different applications?

Yes, flywheel rotors can be customized for specific applications, such as grid stabilization or electric vehicles, based on required energy storage capacity, rotational speed, and system design parameters.

What types of motors are used in flywheel systems?

Permanent magnet synchronous motors (PMSM), induction motors, and high-speed synchronous motors are commonly used for their efficiency, high power density, and ability to operate at high rotational speeds.