Advancements in motor design have led to innovations enhancing efficiency, cutting costs, and boosting performance. One key development is the segmented motor core, revolutionizing industries like automotive and renewable energy with its efficiency, flexibility, and scalability.

This article explores segmented motor cores, covering their design, applications, and benefits.

What Are Segmented Motor Cores?

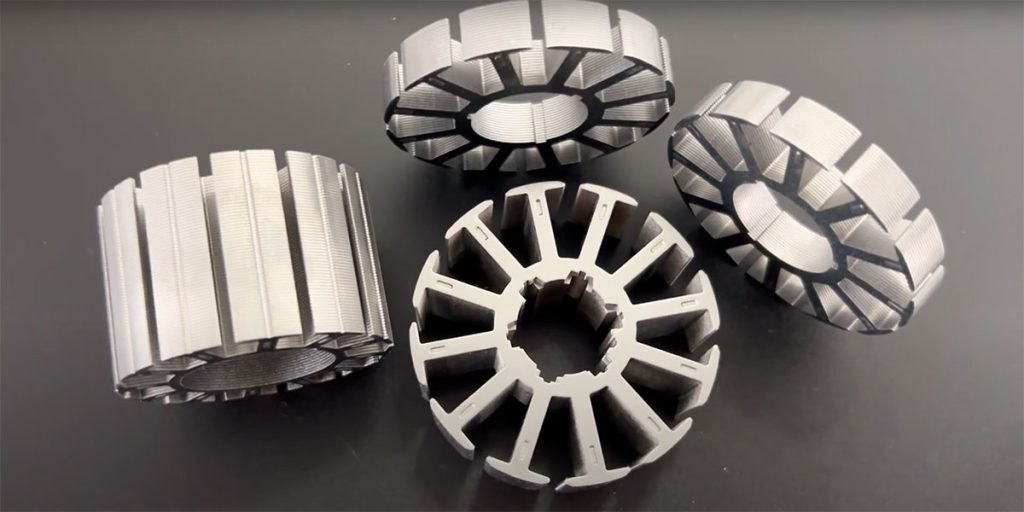

A segmented motor core refers to a motor core composed of individual segments rather than a single solid piece. Traditional motor cores are typically made from laminated sheets of electrical steel, stacked and bonded to form a complete circular or rectangular shape. In contrast, segmented cores divide this structure into smaller, manageable segments. Each segment is meticulously manufactured and later assembled to form the final core structure.

This design not only simplifies the manufacturing process but also allows for the use of advanced techniques that would be challenging or impractical with monolithic cores. Segmented motor cores can be customized to suit specific applications, making them a versatile solution for modern motor systems.

Key Advantages of Segmented Motor Cores

Improved Efficiency:

Segmented motor cores reduce magnetic losses, which are common in traditional cores due to eddy currents and hysteresis. This results in increased overall efficiency, particularly in high-performance applications such as industrial machines and electric vehicles (EVs).

Ease of Manufacturing:

By breaking down the motor core into smaller segments, manufacturers can simplify the production process. This method reduces material waste and gives the core’s dimensions and characteristics more exact control.

Scalability and Modularity:

Different motor sizes and configurations can be easily accommodated by segmented cores. This modular approach enables manufacturers to standardize certain components while customizing others, reducing production costs and time.

Enhanced Thermal Performance:

The segmented design allows for better heat dissipation, as the smaller pieces provide additional surface area and pathways for heat to escape. This feature is especially helpful for high-power motors, as overheating can shorten their lifespan and performance.

Cost-Effectiveness:

Despite their advanced design, segmented motor cores can be more cost-effective than traditional cores due to material savings, reduced labor, and streamlined manufacturing processes.

Applications of Segmented Motor Cores

Segmented motor cores can be used in a variety of applications due to their adaptability. Some of the most notable uses include:

Electric Vehicles (EVs):

The push for sustainable transportation has driven the adoption of segmented motor cores in EV motors. These cores enhance the efficiency and power density of motors, improving vehicle range and performance.

Renewable Energy:

Wind turbines and solar panel trackers benefit from segmented motor cores due to their high efficiency and durability. These applications demand reliable performance in varying environmental conditions, a need that segmented cores meet effectively.

Industrial Machinery:

Segmented cores are used by motors in industrial machinery including robotics, conveyors, and pumps to achieve high efficiency and precision. Additionally, the modular design makes upgrades and maintenance easier.

Consumer Electronics:

Compact and efficient motors in appliances and electronics, such as washing machines and air conditioners, utilize segmented cores to optimize performance while minimizing energy consumption.

Aerospace:

In aerospace applications, where weight and efficiency are critical, segmented motor cores provide a lightweight yet powerful solution for electric propulsion systems and other components.

How Segmented Motor Cores Are Manufactured

The manufacturing process of segmented motor cores involves several steps, each designed to ensure precision and quality:

Material Selection:

The most popular material for motor cores is electrical steel because of its magnetic qualities. Segmented cores may also include advanced materials such as cobalt alloys or nickel-based alloys for specialized applications.

Stamping and Cutting:

Each segment is stamped or laser-cut from sheets of material. High-precision equipment ensures uniformity and consistency in segment dimensions.

Stacking and Bonding:

The individual segments are stacked and bonded using adhesive or mechanical fasteners. This process creates a rigid structure while maintaining the modularity of the core.

Assembly:

Once the segments are prepared, they are assembled into the final core shape. This step often involves advanced automation to ensure alignment and minimize assembly time.

Testing and Quality Control:

Comprehensive testing, including electrical, magnetic, and thermal performance evaluations, ensures that the segmented motor cores meet the desired specifications.

Challenges in Using Segmented Motor Cores

Segmented motor cores have several advantages, but they also present certain difficulties. Some of the potential issues include:

Complex Assembly:

Compared to typical cores, the assembly process may be more complicated because individual segments must be precisely aligned and bonded.

Cost of Initial Setup:

The tooling and machinery required for producing segmented cores can involve higher initial investments. However, over time, labor and material reductions frequently outweigh these expenses.

Potential Weak Points:

The joints between segments may introduce weak points in the core structure. Quality control procedures and sophisticated bonding methods are crucial to reducing this danger.

Design Challenges:

Developing an optimized segmented motor core requires sophisticated design software and expertise, which can pose a barrier for smaller manufacturers.

The Future of Segmented Motor Cores

The development of motor technology is expected to be significantly influenced by segmented motor cores as long as industries continue to place a high priority on performance, sustainability, and efficiency. It is anticipated that developments in manufacturing processes, materials science, and design tools will further expand the potential and affordability of segmented cores.

Emerging trends include:

Integration with Additive Manufacturing:

The use of 3D printing to create complex core segments with precise geometries is an exciting prospect. This approach could reduce waste and open new possibilities for customization.

Improved Materials:

Research into new materials with superior magnetic and thermal properties will drive the development of even more efficient segmented motor cores.

Smart Motor Cores:

Integration of sensors and IoT capabilities into motor cores could enable real-time monitoring and optimization, enhancing performance and reliability.

Conclusion

Motor technology has advanced significantly with segmented motor cores. For a variety of applications, their cost-effectiveness, efficiency, and adaptability make them a desirable option. The future of motors in many industries will be shaped by further research and innovation, which promises to uncover their full potential despite remaining challenges.