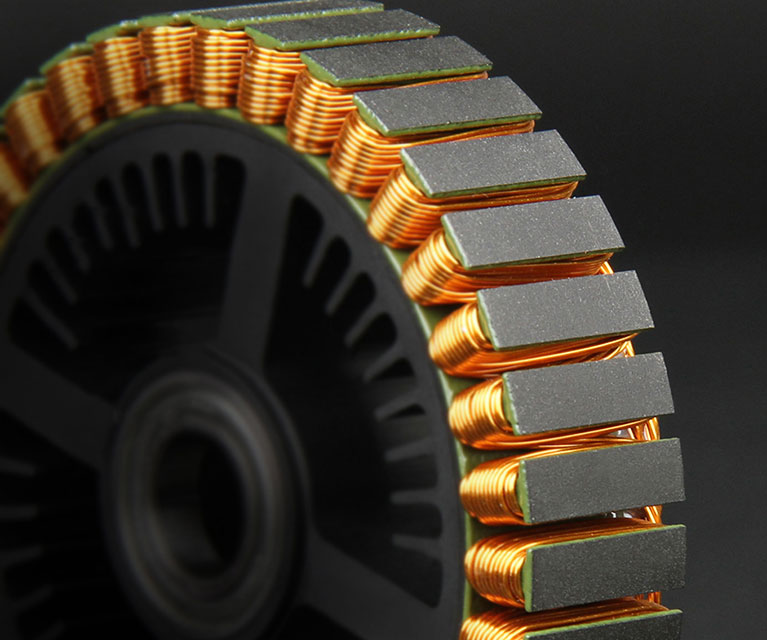

Drone Motor Stator & Rotor Laminations

- Our drone motor stator and rotor laminations are designed for optimal efficiency and lightweight performance, ensuring smooth, high-speed operation in demanding environments.

- With years of experience in precision manufacturing, we deliver top-quality components that enhance the reliability and power of drone motors.

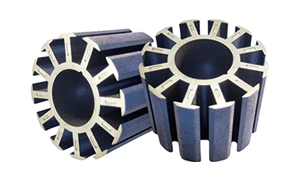

Electric Motors Cores for the Drone Market

- The drone market is experiencing rapid growth, driven by increased adoption across industries such as logistics, agriculture, and surveillance. Electric motor cores are becoming more and more important as drones require greater performance and efficiency.

- These cores directly influence the motor's power output, efficiency, and overall reliability, which are key factors in maximizing flight times, enhancing energy utilization, and reducing weight.

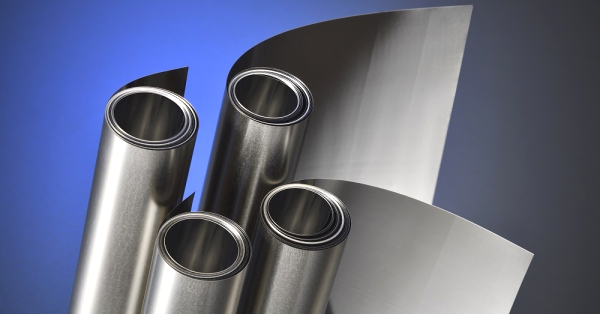

Our Materials Available

Silicon Steel

Amorphous alloy

Propeller Motor Core

Efficient power delivery with lightweight design, ensuring stable propulsion, high thrust, and precise control for optimal drone performance.

Gimbal Motor Core

Precision-crafted for smooth operation, vibration reduction, and steady control, ideal for capturing professional-quality aerial images and videos.

Tail Rotor Motor Core

Compact and durable with reliable torque output, enhancing drone stability, directional control, and seamless maneuverability during complex operations.

Control Surface Motor Core

Designed for quick responsiveness and durable performance, ensuring precise aerodynamics adjustments and accurate flight control for enhanced drone stability.

Payload Motor Core

Energy-efficient motor core supports heavy loads with consistent power, providing secure payload transport while optimizing drone operational efficiency.

Our Customized Solution