Checkout Latest News and Articles

Amid the growing global demand for energy conservation and environmental responsibility, new quality standards are being introduced for stator and rotor laminations. These thin, precision-engineered sheets—essential to electric motors and generators—are now at the heart of efforts to meet increasingly strict energy efficiency regulations across international markets.

Read Article

As the aerospace industry lifts off toward an electrified future, stator and rotor stack manufacturers are quietly but critically enabling the journey. Their innovations in materials, manufacturing, and simulation are shaping the motors that will power tomorrow’s skies.

Read Article

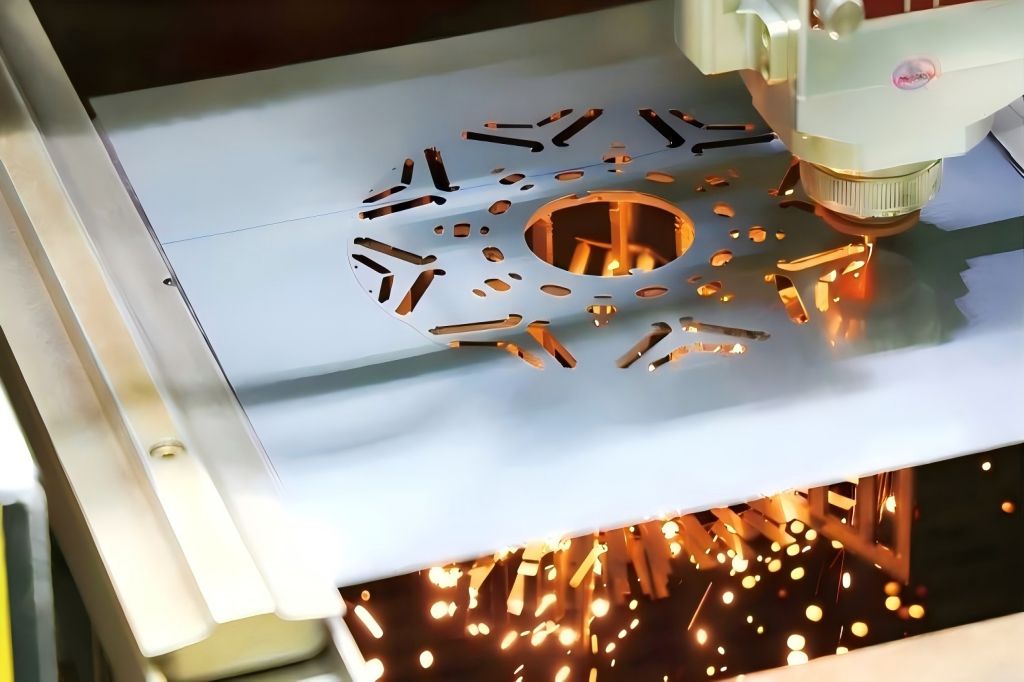

Laser cutting offers a faster, more flexible solution. It creates precise laminations straight from digital designs—quickly, cleanly, and without tooling—helping motor prototypes keep up with fast-changing needs.

Read Article

Laser cutting sample making capabilities are playing a transformative role, especially in the prototyping and customization of motor laminations.

Read Article

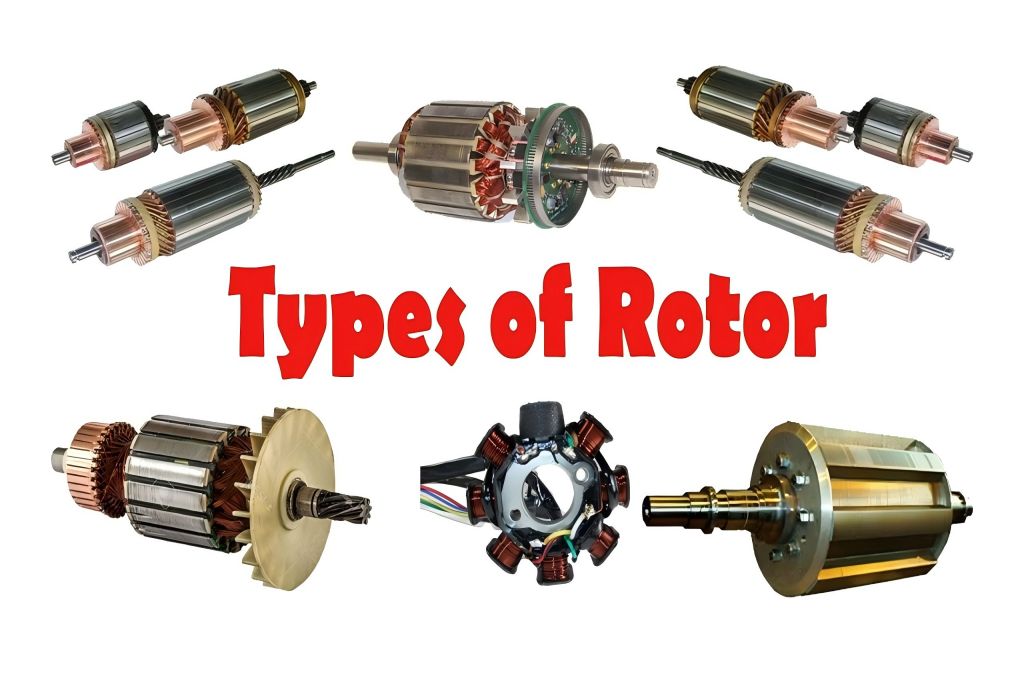

Electric motors are essential in modern technology, and at the heart of every motor is its rotor. An essential component in the transformation of electrical energy into mechanical motion is the rotor. Motor rotors come in a variety of forms, each intended for a particular use and guaranteeing maximum effectiveness, longevity, and performance.

Read Article

Motor stators, the stationary component that produces the electromagnetic field required for rotation, are crucial parts of electric motors. They are, nevertheless, also vulnerable to a number of problems that may affect the longevity and performance of the motor.

Read Article

Precision-engineered stator and rotor laminations play a crucial role in optimizing energy conversion. Ensuring their dimensional accuracy is vital to enhancing motor efficiency and longevity.

Read Article

Ensuring their long-term performance requires proper maintenance of critical components, especially the motor rotor—a key element in converting electrical energy into mechanical motion. To maximize rotor lifespan and vehicle efficiency, EV owners should follow best maintenance practices.

Read Article

Recent advancements, such as automatic stacking and riveting progressive dies, are revolutionizing stator and rotor core production, offering faster production, reduced errors, and significant cost savings.

Read Article

Electric motors are essential in industries like electronics, automation, and EVs. As demand for efficient, high-performance motors grows, so does the need for quality motor parts.

Read Article

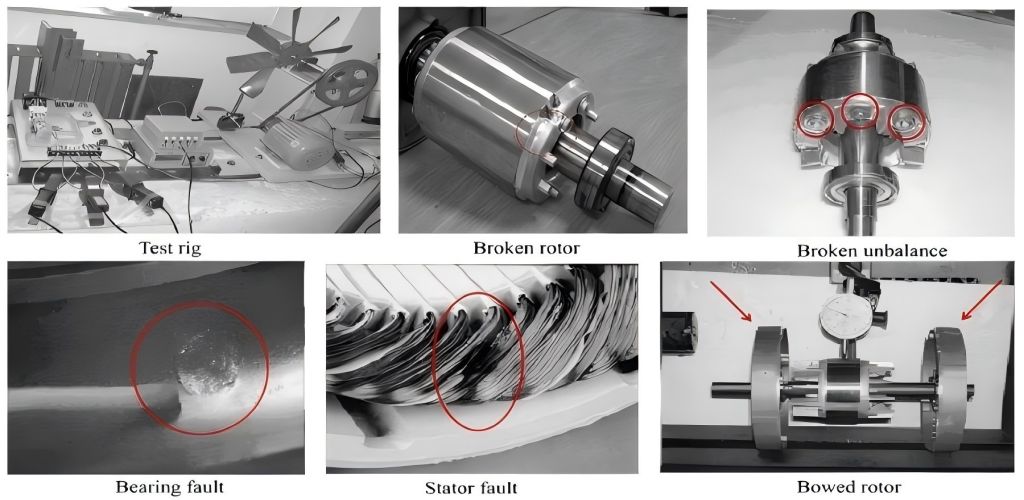

Asynchronous motors, or induction motors, are essential in many industries, powering equipment like pumps, fans, and compressors. However, these motors can experience failures, especially in the rotor and stator.

Read Article

Everything from industrial gear to electric cars and home gadgets is powered by electric motors. At their core are two essential components: the stator and rotor. Each plays a unique role even though they collaborate to transform electrical energy into mechanical power.

Read Article