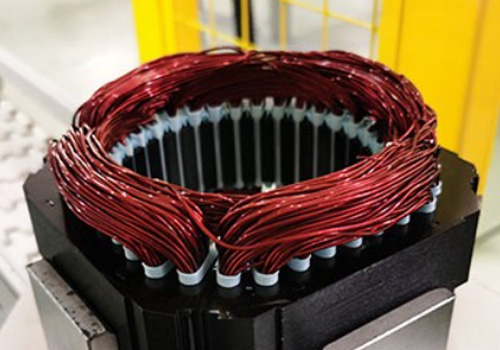

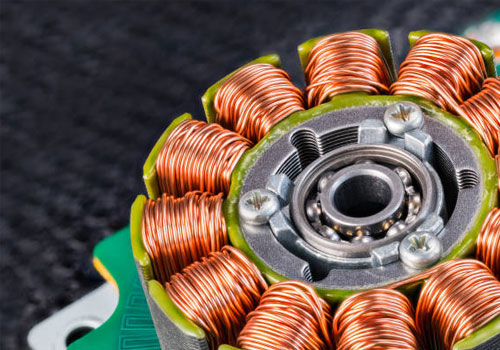

Stator Winding

- Our stator assembly offers flat and round copper wire winding, suitable for both small batches during the sample stage and large batches in later production. Flat wire is ideal for automatic production lines.

- This versatility supports generators and electric motors, offering reliable solutions for diverse energy needs.

- Various Winding Methods

- Stator Diameter Range: 50~500mm

- Pin Winding Range : 150~400mm

- Daily Production Capacity: 5-50 Sets

Stator Winding Process

We offer manual winding for various wire diameters, providing tailored solutions for different motor applications with high-performance results using advanced technology and equipment. Here’s the winding process:

01. Wire Selection

We offer round and flat wire winding options. Flat wire improves efficiency with high slot fill. Round wire range is 50-500mm, pin winding is 150-400mm, 2-8 layers.

02. Manual Winding

Manual winding processes ensure precision, with a production capacity of 5-50 units/day, catering to various motor sizes and wire diameters.

03. Welding & Shaping

Advanced welding machines and shaping tables secure connections and maintain winding integrity, ensuring high quality and proper shape throughout the production process.

04. Advanced Coating and Molding

Our equipment for paint dripping, coating, and 3D molding insulates and protects wire, ensuring durability and high electrical performance for stator windings.

05. Twisting and Laser Welding

Twisting machines and laser welding secure windings, ensuring reliable connections with minimal material impact, resulting in durable windings for enhanced motor performance.

06. Comprehensive Testing

We conduct thorough testing for winding accuracy, insulation quality, and electrical performance, ensuring that each stator winding meets the highest quality and reliability standards.

Stator Winding Material Types

Our stator winding materials include round and flat copper wire, offering high conductivity, efficiency, and excellent performance for motor applications.

Round Copper Wire

- Standard for general motor winding applications.

- Offers good electrical conductivity and stability.

- Easy to handle and wind.

- Suitable for low-to-medium power motors.

Flat Copper Wire

- High slot fill rate for compact designs.

- Enhances efficiency with reduced copper loss.

- Ideal for high-performance motor applications.

- Better heat dissipation and performance.

Based on Winding Process

I-pin Winding

- Simple wire shape, straight “I” formation.

- Lower slot fill, suitable for smaller motors.

- Easy manufacturing and lower cost.

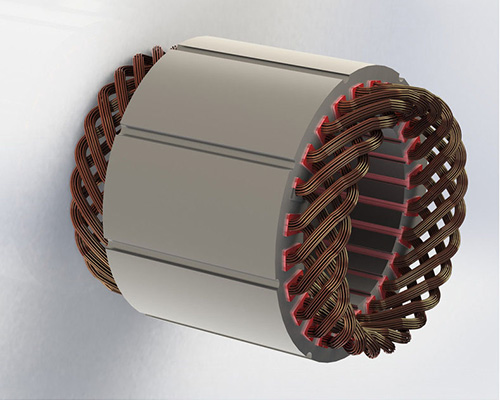

Hairpin Winding

- Bent wire shape resembling a hairpin.

- Higher slot fill, better efficiency.

- Ideal for medium to high-power motors.

X-pin Winding

- Wire bent in an "X" shape.

- Maximizes slot fill and reduces losses.

- Used in high-performance, high-efficiency motors.

Based on Winding Arrangement

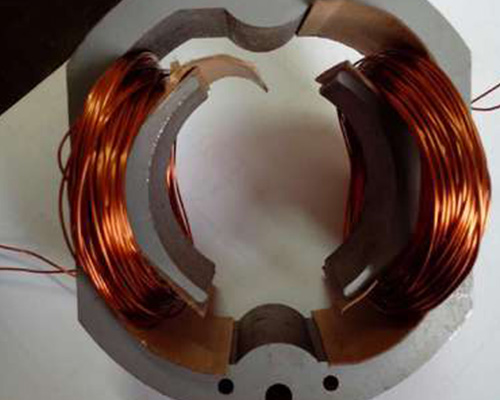

Concentrated Winding

- Coils are wound in closely packed groups.

- Shorter coil paths reduce copper losses.

- Lower manufacturing cost, easier to produce.

- Typically used in smaller, low-power motors.

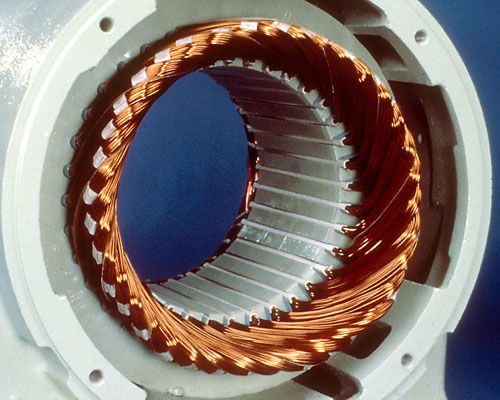

Distributed Winding

- Coils spread across multiple stator slots.

- Improved efficiency and electromagnetic performance.

- Ideal for high-power, larger motors.

- Reduces harmonics and enhances motor stability.

Based on Connection Type

Star Connection

- Coils connected to a central point.

- Provides lower voltage and higher current.

- Common in high-voltage, low-power motors.

- Reduces starting current for smooth operation.

Delta Connection

- Coils form a triangular loop.

- Provides higher voltage and lower current.

- Ideal for low-voltage, high-power motors.

- Efficient at full-load operation.

Based on Coil Construction

Lap Winding

- Coils overlap to form a lap configuration.

- Simple, robust, and cost-effective construction.

- Suitable for low-speed, high-torque motors.

- Provides good mechanical strength and durability.

Wave Winding

- Coils arranged in a wave-like shape.

- Ideal for high-speed, high-efficiency motors.

- Reduces harmonics and enhances performance.

- Requires more turns for compact design.

Based on the Number of Phases

Single-Phase Winding

- Uses one-phase power for low-power motors.

- Simple design, lower cost and maintenance.

- Produces pulsating torque, less smooth operation.

- Common in household appliances and small fans.

Three-Phase Winding

- Uses three-phase power for higher efficiency.

- Provides smoother, continuous torque output.

- Common in industrial and large motors.

- Reduces motor size and improves performance.

Multi-Phase Winding

- Uses more than three phases for power.

- Provides smoother torque with higher efficiency.

- Ideal for specialized industrial applications.

- Minimizes harmonics and enhances motor stability.

Based on Winding Layer

Single-Layer Winding

- One coil per slot, simple design.

- Fewer turns, compact and efficient.

- Used in low-power, low-voltage motors.

- Easier and cost-effective to manufacture.

Double-Layer Winding

- Two coils per slot, more complex.

- Higher efficiency with more turns per coil.

- Ideal for high-power, high-voltage motors.

- Provides better performance and stability.

Based on the Number of Poles

Two-Pole Windings

- High-speed operation, low torque.

- Common in small, lightweight motors.

- Suitable for appliances and fans.

- Simple design, higher efficiency.

Four-Pole Windings

- Moderate speed and torque output.

- Common in industrial motors and pumps.

- Provides better torque than two-pole.

- Suitable for medium-speed applications.

Six-Pole and More

- Low-speed, high-torque operation.

- Ideal for large, heavy-duty motors.

- Common in generators and high-load applications.

- Provides smoother operation with more poles.

Based on the Coil Pitch

Full-Pitch Winding

- Coil spans the entire pole pitch.

- Maximizes motor efficiency and performance.

- Reduces harmonic distortion and losses.

- Common in high-performance, large motors.

Short-Pitch Winding

- Coil spans less than full pole pitch.

- Reduces copper usage and motor size.

- Increases harmonic distortion and losses.

- Suitable for cost-effective, compact motors.

Based on Type of Current

AC Winding

- Used for alternating current motor applications.

- Alternating current flow through coils.

- Common in induction motors and transformers.

- Suitable for high-speed, low-torque motors.

DC Winding

- Used for direct current motor applications.

- Unidirectional current flow through coils.

- Common in small motors and generators.

- Suitable for low-speed, high-torque applications.

Stator Winding Applications

Stator winding applications are crucial in motors, generators, transformers, and electrical equipment, enhancing energy efficiency and operational reliability.

Electric Motors

Stator windings in induction, synchronous, and DC motors generate magnetic fields, converting electrical energy into mechanical motion for driving various devices and machinery.

Generators

In AC and DC generators, stator windings induce electrical current through magnetic fields, converting mechanical energy into electrical power for various industrial applications.

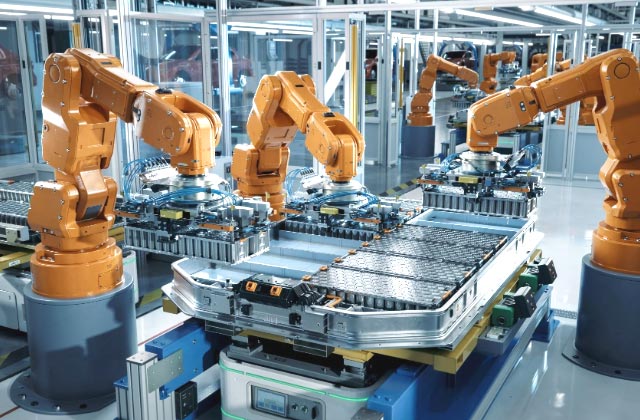

Electric Vehicles (EVs)

Stator windings in electric motors convert electrical energy from the battery into mechanical motion, powering the wheels for efficient, eco-friendly vehicle propulsion.

Industrial Equipment

Stator windings in motors drive industrial equipment, providing mechanical power for machines such as conveyors, pumps, and compressors essential in manufacturing processes.

Robotics

In robotics, stator windings power motors that generate precise torque and motion, enabling robotic arms and systems to perform tasks in automation.

HVAC Systems

Stator windings in HVAC motors power compressors, pumps, and fans, ensuring efficient airflow, temperature regulation, and energy-saving operation in heating and cooling systems.

Renewable Energy Systems

In wind and hydroelectric power generation, stator windings convert mechanical energy into electrical energy, crucial for harnessing renewable energy and supporting sustainable power grids.

Power Tools

Stator windings in power tool motors convert electrical energy into mechanical energy, driving tools like drills, saws, and grinders for efficient construction and maintenance.

Aerospace

Stator windings in aerospace motors and generators power critical systems such as navigation, propulsion, and communication, ensuring reliable operation in demanding, high-performance environments.

General FAQs

How do you test the quality of stator windings?

Quality testing includes checking insulation resistance, verifying winding continuity, conducting high-voltage testing, and ensuring the proper slot fill and winding tension.

Can stator windings be repaired or rewound?

Yes, it is possible to repair or rewind damaged stator windings by removing the old windings and replacing them with new, accurately wound coils.

How do you ensure winding consistency in mass production?

In mass production, automated winding machines, quality control processes, and precise material handling ensure consistent winding results across all stators.

Can stator windings be customized for specific applications?

Yes, stator windings can be tailored for specific applications by adjusting wire material, winding pattern, and coil dimensions to meet power, efficiency, and size requirements.

What is the role of insulation in stator windings?

Insulation prevents short circuits, electrical leakage, and ensures safety. It also helps maintain efficient motor operation by protecting windings from moisture, heat, and other environmental factors.