Company Profile

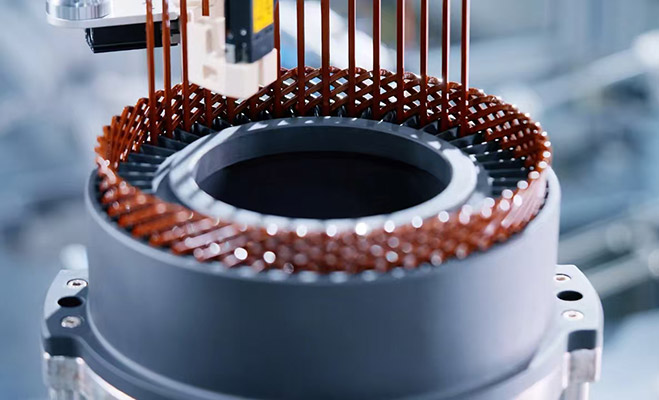

- Jiangyin Gator Precision Mold Co., Ltd. is a renowned manufacturer and supplier specializing in motor core solutions, including stators, rotors, and their laminations.

- Our company operates four production bases across Jiangyin and Yangzhou, covering over 80,000 square meters. Our offerings include motor mold manufacturing, electrical steel stamping, stator winding, rotor assembly, and motor core solutions for both motors and generators.

- We serve diverse industries such as new energy vehicles, robotics, wind power, rail transit, and ultra-efficient motors, providing high-quality products and exceptional services.

Our Production Bases

Our Jiangyin base spans over 60,000 square meters and is equipped with 20 high-speed stamping machines (Nidec and AIDA), 16 automatic production lines, and precision measuring tools like Zeiss and Hexagon. It also features a compound stamping base and winding base, providing comprehensive motor core solutions.

Yangzhou base, located in the Puxi Intelligent Manufacturing Park (300 acres), is equipped with 7 Nidec and 5 Haohui stamping machines, 15 automatic lines, and advanced dust-free workshops, ensuring high production capacity and stringent quality control.

Advanced Manufacturing Facilities

Production Equipment

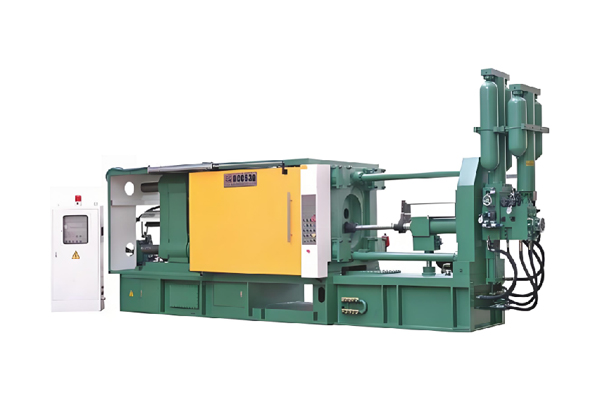

We are equipped with state-of-the-art production machinery, including high-speed stamping machines from Nidec and AIDA, laser cutting machines, wire cutting machines, and automatic lines for welding and riveting.

Testing Equipment

The main testing equipment includes: Zeiss three-coordinate measuring machine, Hexagon image measuring machine, American Micro Vu 2D projector, drawing force meter, iron loss tester, deflection tester, insulation resistance tester, and more.

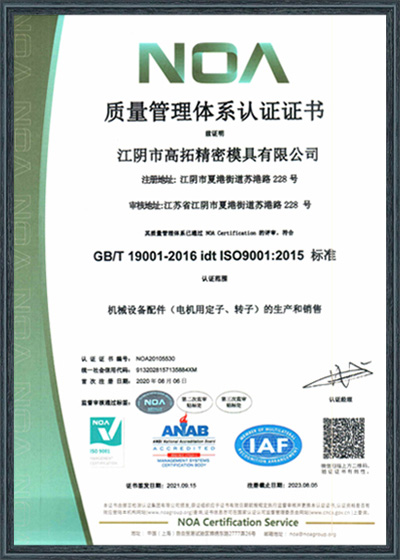

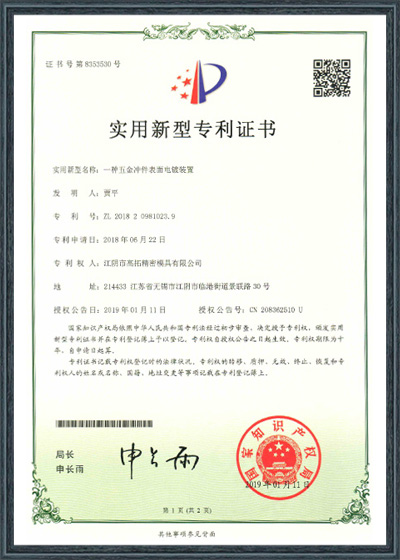

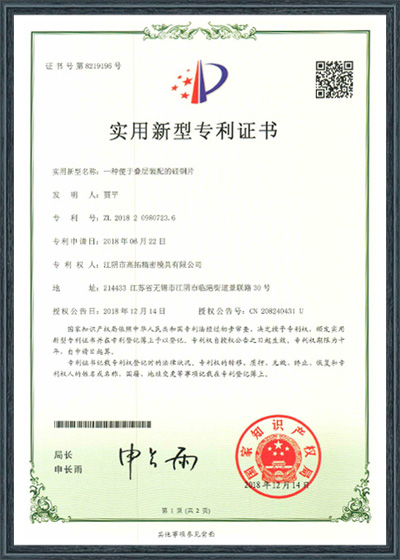

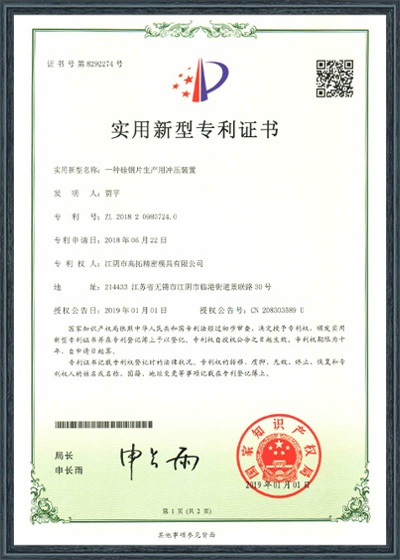

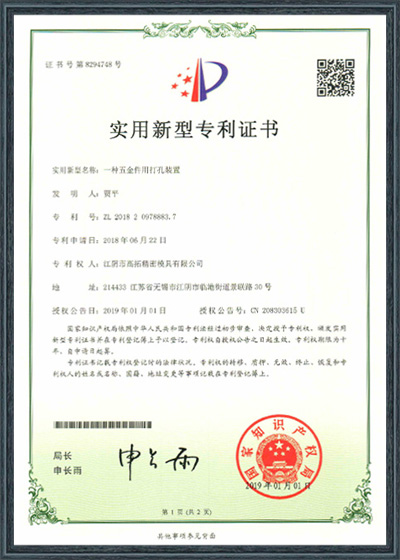

Our Certificates